We believe that careful pre-planning is essential to the project's successful execution. A flow chart created by our manager will be used for the project. To ensure that the projects are turned in by the due dates, we determine the critical paths and create timetables appropriately.

Our seasoned experts examine the project using the normal procedure, keeping an eye out for any information that might be lacking that is necessary for project details. Before we actually begin working on it, our team has a proper set of questions and a thorough examination.

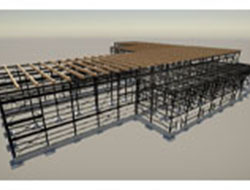

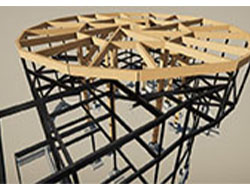

Our modeling, detailing, and erection department experts complete the task in accordance with AISC requirements. Everyone collaborates kindly on one project at a time, which results in better quality and on-time submission.

We send the initial approval for verification. Following the response, we send the designs for field verification and reapproval. Our team distributes the final fabrication package, which includes CNC files, DWG files, gather sheets, erection sheets, KISS files, material files, field bolt summaries, etc., after obtaining final customer confirmation.